équipement de séchage par pulvérisation pour laboratoires de grande qualité de 1,5 l

& nbsp; Le séchoir par pulvérisation à l'échelle de laboratoire convient à la production dans les universités, les instituts de recherche et les entreprises de produits chimiques alimentaires et pharmaceutiques. & nbsp;

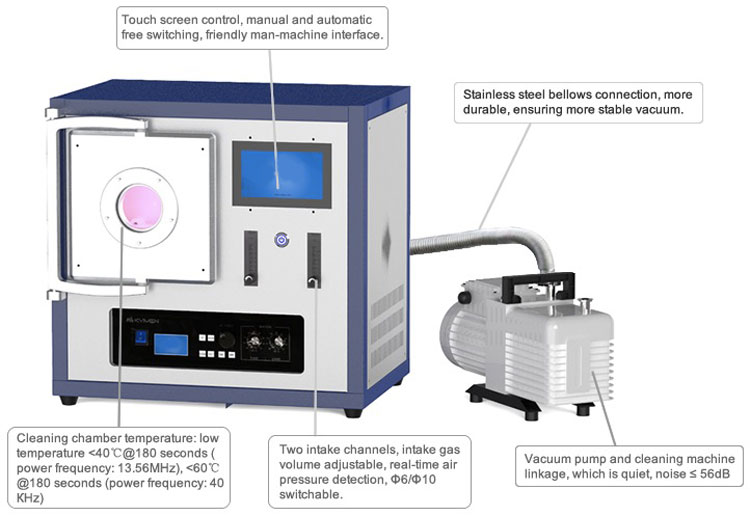

The principle of plasma cleaning is to generate plasma to ionize the molecules in the gas to form charged particles and free radicals. These high-energy particles can react with surface contaminants to decompose or remove them, while increasing the surface energy of the material and improving its adhesion.

Plasma cleaning machines generate plasma through discharge, that is, in this case, charged particles gather together to generate electric and magnetic fields. These charged particles generate high heat and heat when they move. The plasma impacts the surface of the object, knocking away the pollutants, thereby cleaning the surface. In addition, the plasma will also react chemically with the surface of the object to produce volatile materials to treat these pollutants. This reaction will cause changes in the microstructure of the surface of the processed object, which can be etching, roughening, or forming a tight cross-linking layer, or introducing oxidized polar groups, thereby improving the wettability and adhesion of the surface.

The working principle of plasma cleaning machine mainly includes the following steps:

Gas ionization: First, the plasma cleaning machine introduces gas (usually air, nitrogen or argon) into the arc area through a nozzle. Through a high-frequency power supply, the gas is heated to a high temperature, ionizing it to form a plasma.

Arc formation: The power supply generates a high voltage between the electrodes, which causes the gas to ionize and form a stable arc. This arc is the core of the plasma machine, which can produce high temperature (up to thousands of degrees Celsius) and high energy plasma flow.

Cutting or welding: The plasma jet is ejected through the nozzle at high speed, with extremely high temperature and kinetic energy. When it is directed at the material to be cut or welded, the plasma jet quickly heats the material, causing it to melt and evaporate, thereby achieving cutting or welding.

Shielding gas: During the cutting process, shielding gas is usually discharged to help cool the electrode, protect the cutting area, and reduce oxidation. This process makes plasma machines efficient, precise and clean in the metal processing industry.

Working process of plasma cleaning machine

First, a gas (such as oxygen or argon) is introduced into the chamber, and then the gas is ionized under the action of a high-frequency electric field to form a plasma. Next, the active particles in the plasma react with the surface to be cleaned, removing pollutants and impurities, and ultimately forming a clean surface. This process can effectively improve the adhesion and surface properties of the material.

Plasma cleaning machine application

Plasma cleaning machines are widely used in semiconductor manufacturing, optoelectronic devices, medical devices, automotive industry, and aerospace. They are mainly used to remove surface contaminants, enhance surface adhesion, and improve material wettability.

In semiconductor manufacturing

Plasma cleaning technology has greatly improved production efficiency and product quality in semiconductor manufacturing

In the manufacture of optoelectronic devices

Surface cleaning: In the production process of optoelectronic devices, plasma cleaning can remove organic pollutants and particles on the surface of photosensitive materials and transparent conductive films to ensure the stability of device performance.

Improve adhesion: Plasma treatment can change the chemical properties of the material surface and increase its surface energy, thereby enhancing the adhesion of coatings and adhesives and improving the overall performance of optoelectronic devices.

Remove oxide layer: In the production of some optoelectronic devices, it is necessary to remove the oxide layer on the surface of the material. Plasma cleaning can effectively achieve this and ensure good electrical and optical properties.

Improve optical performance: Through plasma treatment, the optical properties of the surface of optoelectronic devices, such as reflectivity and transmittance, can be optimized, thereby improving the efficiency of the device.

Microstructure processing: In some high-precision applications, plasma cleaning can be used for micro-machining to help prepare complex microstructures and improve device performance.

In the automotive industry,

Surface treatment: Plasma cleaning can effectively remove grease, dirt and oxides from the surface of automotive parts, providing a clean base for subsequent painting, bonding or welding, and improving adhesion.

Processing of plastic parts: In automotive interiors and exteriors, plastic parts often need to be plasma treated to enhance their surface energy and coating adhesion.

Cleaning of fuel system components: Plasma cleaning can be used to clean the surface of key components such as fuel injection systems to ensure their working efficiency and life.

Cleaning of electronic components: In electrical and electronic systems, plasma cleaning can be used to remove welding residues and surface contamination to ensure the reliability of electrical contact.

Environmentally friendly cleaning: Plasma cleaning is an environmentally friendly cleaning method that reduces the use of chemical solvents and helps meet increasingly stringent environmental regulations.

These applications help improve the overall performance, quality and durability of automobiles.

un service en ligne

un service en ligne +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529