équipement de séchage par pulvérisation pour laboratoires de grande qualité de 1,5 l

& nbsp; Le séchoir par pulvérisation à l'échelle de laboratoire convient à la production dans les universités, les instituts de recherche et les entreprises de produits chimiques alimentaires et pharmaceutiques. & nbsp;

Introduction: Intelligent transformation of industrial equipment

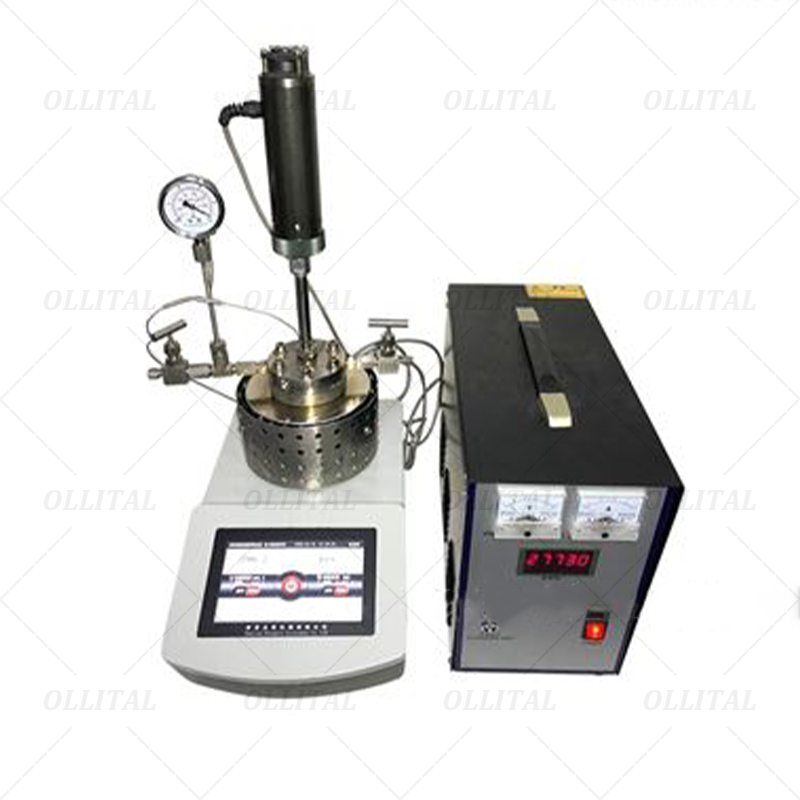

In high-demand fields such as chemical, pharmaceutical and bioengineering, mechanical stirring reactors have always been key equipment. In recent years, with the development of Industry 4.0, touch-screen mechanical stirring reactors, as an intelligent equipment, have gradually replaced traditional reactors, bringing a new experience of convenient operation and precise control to industrial production. The emergence of this equipment not only simplifies the operation process, but also greatly improves production efficiency and product quality.

Technical breakthrough of touch-screen mechanical stirring reactor

Touch operation simplifies the process: Compared with the traditional mechanical button operation method, the mechanical stirring reactor equipped with a touch screen has undergone a major upgrade in the user interface. The introduction of high-definition touch screens enables operators to adjust reaction conditions such as temperature, pressure and stirring speed more intuitively and quickly. This intuitive interface design not only reduces human operating errors, but also makes the management of complex processes simpler and more efficient.

Precision control and digital management: Modern touch-screen reactors have built-in advanced automatic control systems that can accurately set and adjust various operating parameters to ensure the stability of the reaction process. In addition, the equipment also has real-time data recording and analysis functions, which facilitates operators to track and optimize production processes. Digital management methods provide strong support for scientific research and industrial production, making process optimization and quality control more accurate.

Safety protection and automation improvement: Reactors equipped with touch screens usually integrate multiple safety protection measures, including automatic alarm and emergency shutdown functions. Intelligent control systems can automatically take countermeasures when abnormal conditions are detected, effectively reducing the risks in the production process. In addition, this equipment has greatly improved the degree of automation, reduced the need for manual intervention, and further improved production efficiency and safety.

Market potential and application prospects

Wide application in multiple fields: Touch screen mechanical stirring reactors show great application potential in multiple industrial fields, especially in the pharmaceutical and fine chemical industries, where accurate reaction condition control is the key to ensuring product quality. With the deepening of industrial intelligence, the importance of this equipment in production has become increasingly prominent and has been favored by more and more companies.

Future market growth: With the increasing demand for intelligent equipment in industrial production, the market demand for touch screen mechanical stirring reactors is also expanding. Enterprises have gradually realized that the use of intelligent equipment can not only improve production efficiency, but also effectively reduce operational risks, so the market prospects of this equipment are broad.

Conclusion

The emergence of touch-screen mechanical stirring reactors marks an important step for industrial equipment to move towards intelligence and precision. With its advanced touch operating system, precise control technology and efficient safety protection functions, this equipment will play a more important role in future industrial production, providing strong guarantees for production efficiency and product quality in various industries.

un service en ligne

un service en ligne +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529